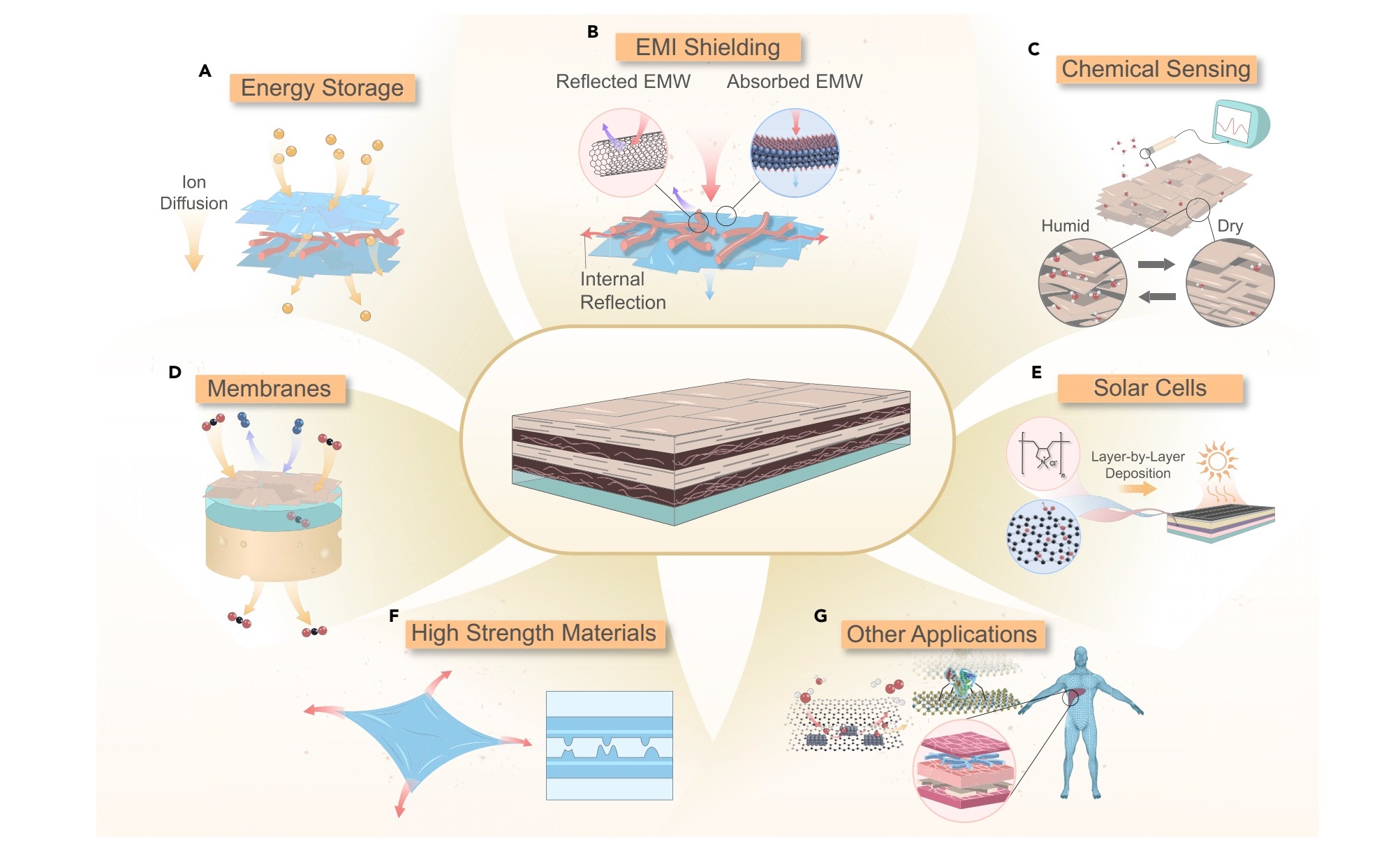

Layer-by-layer (LbL) assembly is a powerful and broadly applicable nanofabrication technique which involves the sequential adsorption of polyelectrolyte pairs to generate multilayer thin films. This technique enables the generation of nanoscale coatings with highly controllable properties which include opacity and color, mechanical strength, and electrical and ion conductivity.

Our work with the LbL technique has involved the generation of functional multilayer films useful in fuel cells and microscale batteries. Specifically, we have generated fuel cell membrane-electrode-assemblies (MEA) using LbL and showed that ultrathin, homogeneous multilayers with integrated Pt-catalyst exhibit increased Pt-utilization through optimization of the triple-phase-boundary (TPB) region. Additionally, we have developed a spin-spray LbL technique (SSLbL) that allows superior nano-level control over deposition and drastically reduced processing times (on the order of 13 sec vs. 45 min for conventional dip-coating LbL). We also demonstrated the ability to tune the conductivity of polymer-composite multilayer films by varying deposition conditions like spray times, spin rate, active heating, and polyelectrolyte concentration. The SSLbL technique has been used to generate ultrathin lithium battery electrodes with improved energy and power densities. Recent modeling work has also supplemented our understanding of electrical percolation in conducting composite multilayers.

We also recently developed a highly conductive MXene-CNT polymer composite film for electromagnetic interference (EMI) shielding using SSLbL. The optimized LbL composite film shows unprecedentedly stability in ambient air over 1 month. Some other related works are still ongoing.